Overhead power lines are an important component of the electrical grid that allows the distribution of power over a long distance. The safety and dependability of these systems are strongly determined by the quality of the components, especially the clamping solutions to hold the cables and conductors. Emerging clamping technologies, including the MV Tension clamp for ABC, have contributed immensely to the installation, maintenance, and operation of overhead power lines.

Clamping solutions are essential connectors and they are used to make sure that the cables remain in place in the most extreme conditions, high winds, as well as temperature changes. Due to the rise in power demands and the need to have efficient and reliable power transmission, these innovations are becoming important in how utility companies design and maintain overhead networks.

The Role of Clamping Solutions in Overhead Power Lines

Clamps are required to support and hold as well as maintain the integrity of conductors in an overhead power system. They are used to fix the cables and to ensure that the lines are tensioned in the right way to avoid dropping or swinging. Clamping solutions are applied at the different points of the transmission lines, such as cable joints, pole connections, and at the ends of the lines.

The conventional methods of clamping, though acceptable, normally have problems like corrosion, wear, and uneven tension, and thus may result in failures or may need repetitive repairs. Advanced clamp designs have resolved these issues through superior materials, improved engineering, and tensioning systems.

Types of Clamps Used in Overhead Power Lines

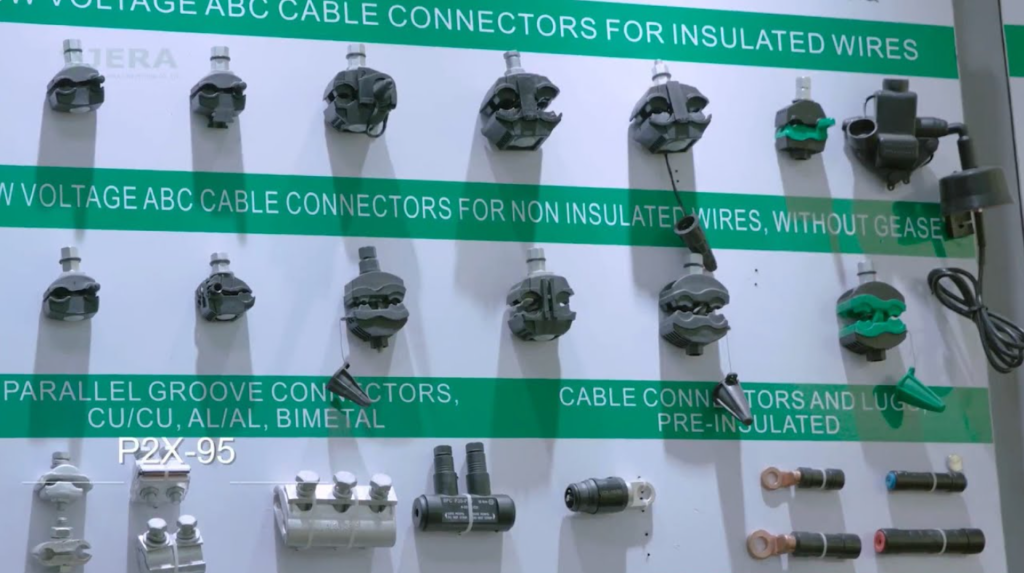

Overhead power lines use various types of clamps, which are oriented to a particular use. Among the most typical ones, there are:

Tension Clamps

Tension clamps are available to keep the ends of the lines in place, and they are used to keep the proper tension on the lines. These are needed to withstand the forces exerted on the lines in windy conditions and may stop the conductor from snapping or moving.

Suspension Clamps

This is employed to support the conductors at intermediate points on the line. Suspension clamps enable the cables to be in a free-flowing state and remain stable.

Dead-End Clamps

These are used to clamp power poles on the ends of conductors. They play a very important role in ensuring that the lines do not shift or detach because of forces.

Splice Clamps

These are applied in bringing two parts of a conductor or cable together. The splice clamps are used so that the electrical connection is stronger and long-term.

Enhancing Durability and Longevity

The wear and tear of overhead power lines due to environmental factors such as moisture, wind, and temperature variation is one of the largest challenges in overhead power lines. The corrosion of traditional clamping solutions was also a common problem and resulted in poor quality in keeping the cables firmly in position.

This has been overcome by the development of clamping technology that entails the use of high-quality and non-corrosive materials. The Clamps of today are mostly composed of stainless steel and aluminum, and other superior alloys that are more resistant to corrosive weather conditions. A number of these materials are also made lightweight, such that they are easy to install and put less strain on the structure.

Besides the enhancement of materials, most current clamping solutions are developed with the intention of having a longer service life. Not only are these clamps more resistant to environmental degradation, but they are also made to accommodate more load and stresses in the long term to guarantee the reliability of the power line system.

Streamlining Installation and Maintenance

The overhead power lines installation and servicing can be complicated and time-consuming. The traditional clamps were usually either too complex in terms of their tools or they required extra manpower to install the clamp, and that might cost more labor and may still lead to a mistake during installation.

More recent clamping systems, including quick-connect and adjustable tensioning systems, are much more effective to install and less subject to error. The innovative clamps are made in such a way that they can easily be fitted without using many tools, thus, the cost of installation is minimized, and they can be installed within a relatively short time.

Also, these sophisticated clamping systems are usually created for easy maintenance. Their well-built construction and superior materials imply that the number of clamps that utility companies need to replace or fix over the life of the power line is reduced, which saves the cost of maintenance.

Improved Safety Features

The design and operation of overhead power lines are very crucial issues for safety. Any malfunction of the clamping system might lead to electric cuts, equipment damage, or even injuries. The next level of clamping solutions is those that are more advanced, which include the features that minimise the chance of failure, and the overall reliability of the system is improved.

As an example, most modern clamps have an internal mechanism that assists in maintaining consistent tension during their working life, eliminating chances of slackness in their line or movement of the conductor. Also, the clamps are made to be more responsive to dynamic loads like those induced by storms or strong winds, so that the power lines are not damaged and rendered useless.

Moreover, other new clamps have features that assist in eliminating electrical faults. For example, certain clamps have insulating materials that do not allow direct contact between the conductor and the metallic side of the clamp (so the short and grounding are reduced).

Reduced Downtime and Operational Costs

The modern clamping solutions being offered in the market not only enhance the safety and reliability of overhead power lines, but they also contribute to the minimization of the downtime of their operations. Previously, when a power outage happened due to the breaking of the clamping, it was common to require much time to repair, because damaged clamps needed to be replaced or repaired. This disconnection not only impacted the utility company, but also on customers who depended on electricity.

By implementing the use of high-tech clamping options, there is a low probability of clamping issues. In the cases where the clamping systems require maintenance, the latest technologies make the maintenance more rapid, which reduces the disruption to a minimum and provides power lines with working capacity.

These new clamps can save utility companies on long-term operations costs by lowering replacement and repair rates. They are a smart investment in utility companies that are planning to modernize their infrastructure due to their high performance and low maintenance needs.

Conclusion

Advanced clamping solutions are transforming the manner in which overhead power lines are constructed, maintained, and operated. These innovative solutions have been useful both to utility companies and consumers in terms of durability and safety, efficiency in installation, and minimization of downtime. The current technology on clamps, e.g., the MV Tension clamp on ABC, is contributing to the fact that overhead power lines are now sustainable in the long term. Through these advancements, it is more secure with regard to the future of power transmission.