Metal fabrication is the backbone of modern manufacturing. From industrial machinery and energy systems to electronics, transportation, and consumer products, nearly every engineered product relies on fabricated metal components. From a metal manufacturing expert’s perspective, understanding metal fabrication processes and techniques is essential for choosing the right method, controlling costs, and achieving consistent quality.

This ultimate guide explains what metal fabrication is, the most common processes used today, how different techniques compare, and where TMNetch metal etching service fits into the broader fabrication landscape.

What Is Metal Fabrication?

Metal fabrication is the process of transforming raw metal materials into finished or semi-finished parts through cutting, forming, joining, and finishing operations. It typically starts with metal sheets, plates, tubes, or bars and ends with components ready for assembly or direct use.

Unlike simple machining, metal fabrication often combines multiple processes to achieve the desired geometry, strength, surface finish, and functionality.

Common industries that rely heavily on metal fabrication include:

- Industrial equipment and automation

- Electronics and electrical systems

- Automotive and transportation

- Energy and fuel cell systems

- Medical and laboratory equipment

Common Metals Used in Fabrication

Before discussing processes, material selection must be considered. Fabrication techniques are closely tied to material properties such as strength, ductility, corrosion resistance, and thickness.

Frequently fabricated metals include:

- Stainless steel for corrosion resistance and strength

- Carbon steel for structural and cost-sensitive applications

- Aluminum for lightweight components

- Copper and brass for electrical and thermal performance

- Nickel and specialty alloys for high-temperature or chemical environments

Each fabrication process interacts differently with these materials, influencing precision, surface quality, and cost.

Core Metal Fabrication Processes

Cutting Processes

Cutting is usually the first step in metal fabrication. Its purpose is to separate material into usable shapes or blanks.

Common cutting techniques include:

- Laser cutting, known for speed and accuracy on thin to medium sheets

- Plasma cutting, effective for thicker steel plates

- Waterjet cutting, suitable for heat-sensitive materials

- Mechanical shearing and sawing, used for simple geometries

Cutting method selection depends on thickness, tolerance requirements, and edge quality expectations.

Forming and Bending

Forming processes reshape metal without removing material. These techniques are widely used to add stiffness, create enclosures, or achieve functional geometry.

Typical forming methods include:

- Press brake bending

- Roll forming

- Stamping and punching

- Deep drawing and hydroforming

While forming is efficient for high-volume production, tooling costs and material springback must be carefully managed.

Joining and Assembly

Once individual parts are shaped, they must be joined to form assemblies or structures.

Common joining techniques include:

- Welding (MIG, TIG, spot welding)

- Brazing and soldering

- Mechanical fastening (rivets, screws, inserts)

The choice of joining method affects structural strength, appearance, and long-term durability.

Finishing Processes

Finishing improves surface appearance, corrosion resistance, and functional performance.

Typical finishing operations include:

- Polishing and brushing

- Electroplating and coating

- Anodizing and passivation

- Heat treatment

In many industries, finishing is as critical as fabrication itself, especially for precision or exposed components.

Precision Fabrication Techniques

As product designs become more compact and complex, traditional fabrication methods may struggle to deliver the required precision. This has driven adoption of advanced fabrication techniques, including chemical etching.

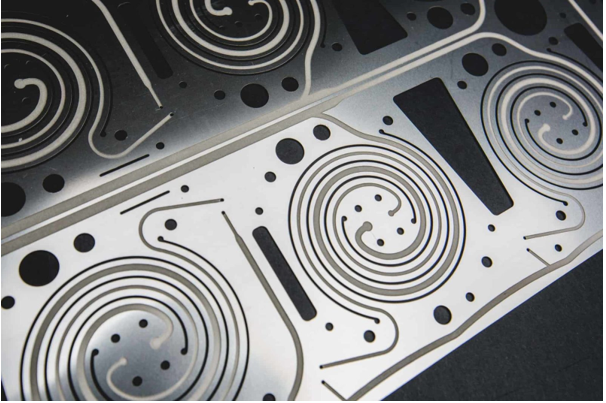

Chemical Etching (Photochemical Etching)

Chemical etching removes metal using controlled chemical reactions guided by a photoresist pattern. From a manufacturing expert’s viewpoint, it occupies a unique position in metal fabrication because it:

- Applies no mechanical force or heat

- Produces burr-free, stress-free edges

- Enables very fine features and complex patterns

- Requires no hard tooling, reducing upfront cost

Chemical etching is especially effective for thin metal components, intricate geometries, and applications where flatness and precision are critical.

Where Chemical Etching Fits in Metal Fabrication

From an industry standpoint, chemical etching does not replace all fabrication methods. Instead, it complements them.

Chemical etching is ideal when:

- Parts are thin and easily deformed by stamping

- Burrs or heat-affected zones are unacceptable

- Design iteration speed matters

- Fine apertures, slots, or patterns are required

Typical applications include electronic components, metal mesh filters, shims, bipolar plates, shielding parts, and precision industrial components.

TMNetch Metal Etching Service

Within the metal fabrication ecosystem, TMNetch metal etching service focuses on precision photochemical etching for industrial and high-performance applications.

TMNetch Capabilities

From a metal manufacturing expert’s perspective, TMNetch provides several practical advantages:

- Specialized in photochemical etching since 2011

- ISO 9001:2015 certified, ensuring consistent quality control

- Supports a wide range of metals, including stainless steel, copper, brass, aluminum, nickel alloys, titanium, and specialty materials

- Capable of producing high-precision etched components with complex geometries

- Suitable for thin to medium-gauge metal sheets, depending on material

- Offers rapid prototyping without tooling investment

- Provides secondary fabrication services, such as plating, surface finishing, bending, and forming

When TMNetch Is the Right Choice

TMNetch metal etching service is particularly well suited for:

- Precision components requiring burr-free edges

- Projects with frequent design changes

- Low-to-medium volume production with high complexity

- Applications where flatness and dimensional consistency are critical

By integrating chemical etching into the fabrication workflow, TMNetch helps manufacturers reduce risk and improve part performance.

Choosing the Right Fabrication Process

From a strategic standpoint, no single metal fabrication process is universally “best.” The optimal approach depends on:

- Material type and thickness

- Part geometry and tolerance requirements

- Production volume

- Budget and lead time constraints

In many cases, combining multiple processes—such as laser cutting followed by forming, or chemical etching combined with finishing—delivers the best results.

The Future of Metal Fabrication

Metal fabrication continues to evolve alongside advancements in materials, automation, and digital design. Precision-driven techniques like chemical etching are gaining importance as industries demand smaller, lighter, and more complex components.

From a manufacturing expert’s view, the future of metal fabrication lies in process integration—selecting the right technique at the right stage to balance performance, cost, and scalability.

Conclusion

Metal fabrication is a broad and essential field that encompasses cutting, forming, joining, finishing, and advanced precision techniques. Understanding the strengths and limitations of each process is key to successful product development.

As designs push the limits of precision and complexity, solutions like TMNetch metal etching service play an increasingly important role within the metal fabrication ecosystem. By leveraging chemical etching alongside traditional fabrication methods, manufacturers can achieve higher accuracy, faster iteration, and more reliable performance across a wide range of industries.